Underwater welders perform welding underwater with specialized welding equipment, often at elevated barometric pressures. These elements introduce various challenges and welders must possess specialized skills and training. The conditions associated with underwater welding are incredibly dangerous and divers should undergo rigorous training with highly specialized instruction. Nothing can be left up to chance.

Wet Welding

Welding underwater can either be performed by wet welding or dry welding. Wet welding describes when a diver has to perform the welder while they’re in the water. There is a specialized welding rod and it employs a similar process to ordinary welding. There are some advantages to this type of welding that include:

● Cost-efficacy

● High-tensile strength

● Access to the welding spot

● No habitat

● No construction

Hyperbaric Welding

Hyperbaric welding is an alternative to wet welding. Hyperbaric welding incorporates a method, by which a sealed chamber around a structure that needs to be welded. Gas fills the chamber and the water is forced out of the hyperbaric sphere, allowing for a dry environment to perform the weld. The advantages of a hyperbaric weld include:

● Welder/diver safety

● Higher weld quality

● Surface monitoring

● Non-destructive testing

Training

Most underwater training programs go beyond underwater welding and incorporate salvage, pipeline construction, repair, rigging, and underwater operations of underwater tools. Underwater welding supplies include jack-hammers, hydraulic drills, and chainsaws. Some programs also include underwater scuba endorsements from the DCBC.

The skills included in these training programs go beyond the typical diving training programs. Individuals interested in a career in underwater diving must understand that the skills incorporated in a diving training program extend well-beyond the scope of this article.

A Deeper Look Into HyperBaric Welding

Some of the dangers of hyperbaric welding come from the continuous fluctuation of air keeping the area safe from toxic fumes. If gasses were to build, hyperbaric welders could suffocate. At greater amounts of pressure, dive teams can use helium mixtures for pressurizing.

Dive teams use helium to pressurize the cabin so underwater welders don’t succumb to nitrogen narcosis or lose consciousness. However, because of the constant influx of air, there is a danger of explosion in the chamber. These issues are not an isolated issue when it comes to underwater welding and surface welders have to deal with this possibility as well. Even in a basic welding shop, welders must practice the safe technique of proper ventilation to keep the air moving through. This keeps excess gasses from accumulating in the area.

A Deeper Look Into Wet Welding

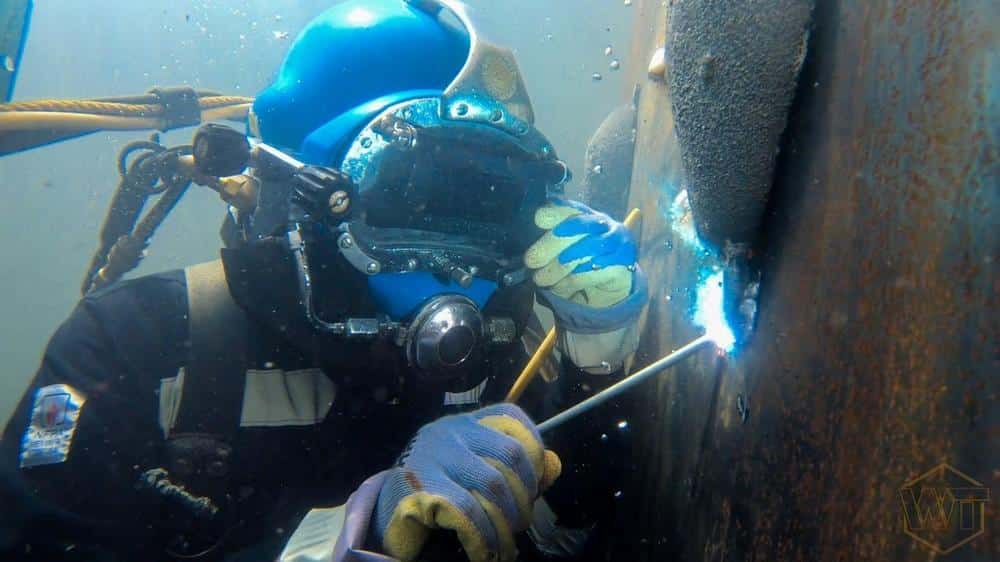

Underwater wet welding typically uses shielded metal arc welding as the principle welding means. In these cases, the welder is submerged in water, wearing dive gear.

How Do Electrons Affect the Process?

How does underwater welding even work? How can you generate a flame while you’re submerged? To understand how this happens, you need to take a look at the electrode at a molecular level. The heat distribution of the electrode to the weld area is controlled through charged electrons.

These are the primary areas of heat movement:

● Cathode

● Anode

● Plasma

The cathode carries a negative charge while the anode carries a positive charge. When the underwater welder strikes the arc, the electrons from the cathode travel down to the anode while positive ions move up toward the cathode.

This exponential particle movement generates enough energy to heat the arc past 5,000 degrees celsius. However, this heat isn’t spread evenly throughout the work area. 665 degrees are applied to the anode and the rest remains at the tip of the cathode.

Underwater wet welding is different from hyperbaric welding. Underwater wet welding insulates the electric cables twice while only using direct current for its power source and typically incorporating negative polarity. The system also typically incorporates a knife switch along the cables. This knife switch keeps the power turned off to the welding stinger.

Once the welder positions themselves for the weld, welder divers communicate to the surface to heat the welding device. At this point, the welding team strikes the electric arc that flows from the waterproof electrode to the metal seam.

How Are Wet Welds Protected?

Wet welds are protected by gaseous bubbles that form around the arc. The bubble is typically composed of specific mixtures of gasses such as hydrogen, carbon dioxide, and carbon monoxide. These waterproof electrodes have a thick material called flux on the outsides. As the electrode burns, the chemical change produces a protective gas bubble around the weld.

How Do Gas Bubbles Affect Visibility?

Underwater wet welders face a unique challenge of their welds producing additional bubbles that rise into the surrounding water. You have the same effect when you breathe while scuba diving underwater. On a wet weld, this hinders visibility and it moves the weld puddle more rapidly. On top of this, the electric arc is affected by the bubbles and the arc runs the risk of collapsing. Experienced underwater divers should be used to this, though it is a risk factor nonetheless.

What Are the Three Most Common Dangers of Underwater Welding?

The three most common dangers of underwater welding are as follows:

Explosions and electrocution: electrocution is a significant threat to underwater welders and it requires them to use specialized waterproof equipment at all times. Underwater welding also produces underwater oxygen and hydrogen gasses, which can cause explosions.

Decompression illness: As with other dive operations, underwater welders work hundreds of feet beneath the surface and they endure dangerous pressure changes. Decompression illness is caused by the reduction of ambient pressure surrounding the body. You can undergo decompression sickness or arterial gas embolisms from this exposure. Arterial gas embolism occurs when bubbles travel through the arteries, causing tissue damage and from a blocked blood flow.

Drowning: Differential pressure can lead to drowning incidents and it can be almost undetectable. When two bodies of water intersect the pressure difference can quickly amount to hundreds of pounds per square inch. These pressure differentials will trap the diver and drown them. Diving gear failures can also drown divers.