3D printing has been around for many years but has only recently become popular in the construction industry. There are many advantages to using 3D printing in construction: it is faster and cheaper and plays a significant role in constructing various artistic elements for buildings. Before we have a look at this fascinating technology that is transforming the construction industry, let’s have a look at what 3D printing is in general.

What is 3D Printing?

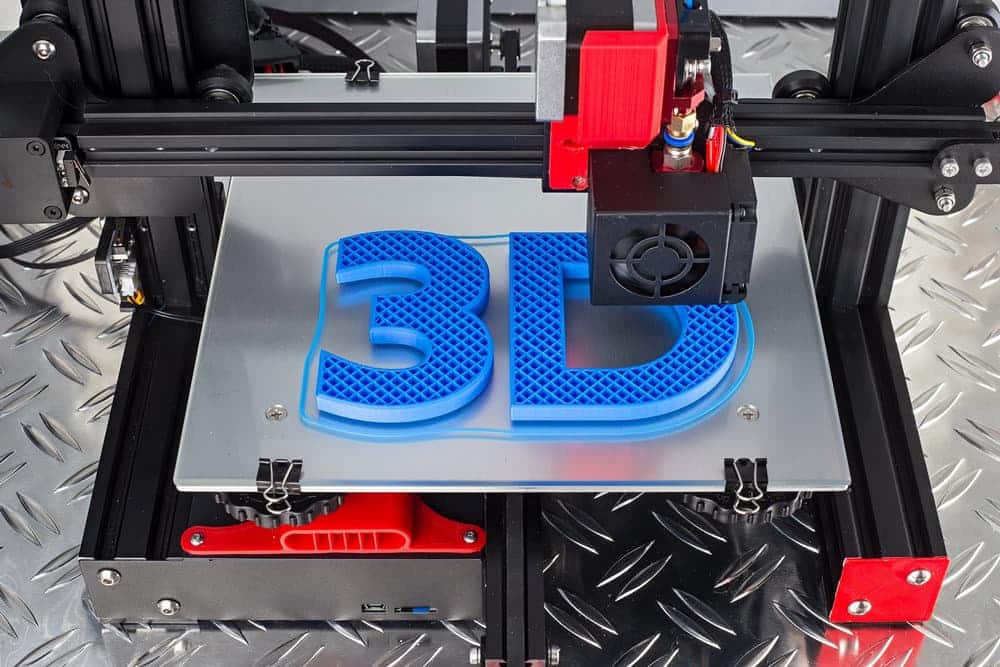

3D printing technology (called Additive Manufacturing) is where physical products are created from digital files. A 3D file is created in CAD software, and a file format supported by 3D printers is generated (usually STL or OBJ), or it can be sliced, and code containing the instructions for the 3D printer is generated (G-code). The code includes instructions like how to move the axis of the printer and the amount of filament to extrude to lay the layers of material in different shapes successfully.

3D printing technology can be used to create virtually any shape or form. It offers limitless possibilities for design and customization. Objects can be made with intricate details and features that would be impossible to achieve using traditional manufacturing methods.

How 3D Printing Is Transforming the Construction Industry

There are many ways in which additive manufacturing is transforming the construction industry. Here are the six main ones:

1) Creating Prototypes of Buildings

One of the most prominent applications of 3D printing in the construction industry is the creation of prototypes. 3D printed prototypes can be used to test out different designs before committing to a final version. This can save time and money by allowing architects and engineers to catch errors early in the process.

3D printed prototypes can also be used to assess the feasibility of a proposed design. By examining the 3D printed model, decision-makers can better understand how a building will look and feel before it is built.

To create prototypes, you don’t need an expensive machine. You can get the best 3D printer under $1000 that can do a fantastic job.

2) The Use of 3D printing Can Help Reduce Construction Waste

The construction industry is responsible for a large amount of waste generated yearly. In fact, according to ScienceDirect, nearly 30% of construction materials usually end up as waste. Much of this waste ends up in landfills, where it takes up valuable space and can release harmful pollutants into the environment.

3D printing offers a potential solution to this problem, as it can be used to create building components from reclaimed or recycled materials. In addition, 3D-printed buildings can be disassembled and recycled at the end of their lifespan, reducing the amount of waste produced.

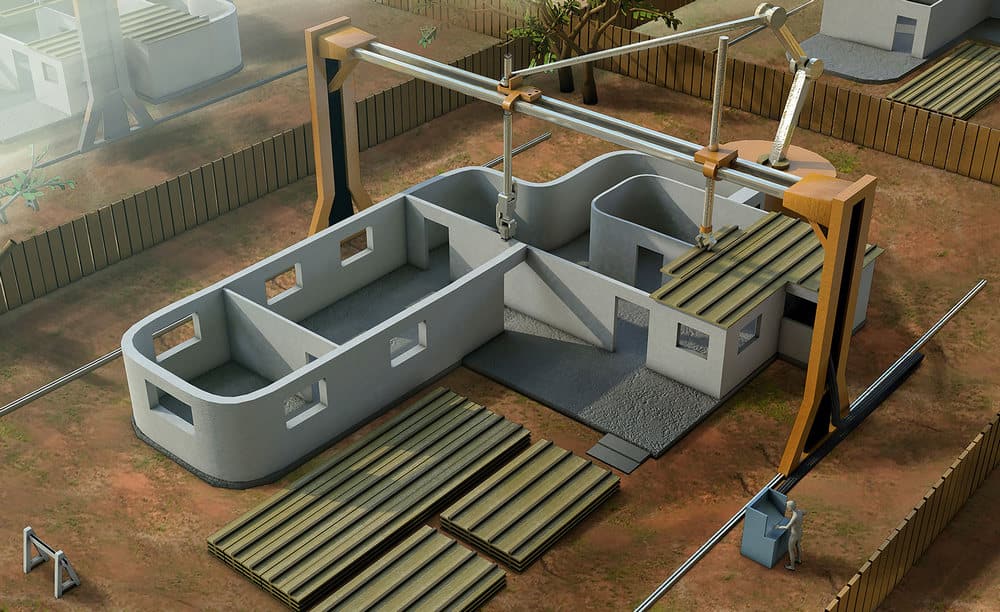

3) Constructing Homes With 3D Printing

3D-printed homes can be built quickly and cheaply, offering a high degree of customization. In addition, these homes are often more environmentally friendly as they generate less waste.

3D-printed buildings are still in the early stages of development, but they have already shown great promise. Only time will tell if they will become a common sight in our cities and towns. However, if they continue to progress at their current rate, they could play a major role in solving the global housing crisis.

4) Creating Houses on Mars

The Red Planet has a hostile environment that is not conducive to traditional construction methods. But 3D printing can be done in any condition and even much faster when it comes to construction, making it the perfect technology for building homes on Mars.

Recently, we even saw Nasa backing the construction of homes on Mars. AI Space Studio company was able to construct a house on Mars that looked exactly like a beehive. Each of those houses could accommodate at least four astronauts.

5) 3D Printing is Used to Make Artistic Elements in Buildings

3D printers can be used to create anything from intricate friezes and sculptures to large-scale murals and reliefs. In many cases, 3D-printed elements can be incorporated into the fabric of a building, such as in the form of facade panels, window treatments, or even decorations, to add beauty and intrigue to a building. A 3D modeling software can be used to prepare the designs of the artistic elements, sliced and then sent to the printer for production.

6) Makes it Easier to do Presentations of Constructions

3D printing is making it easier to present architectural and construction projects. Because 3D printers can create highly detailed and accurate models, they can show potential clients what a finished project will look like. This can help to give them a better understanding of the scale and scope of the project, and it can also help to generate excitement and interest.

Limitations of 3D Printing in Construction

As with any technology, there are limitations to what can be accomplished with 3D printing in construction. Here are some of such limitations:

- The range of materials used in additive printing is currently quite limited. This restricts the types of construction projects that can be undertaken using this technology.

- The cost of 3D printers and the materials required are still quite high. Large 3D printers are costly, especially for many construction companies working on a tight budget.

- The energy requirements of 3D printers can be quite high. Large 3D printers use a lot of power to do the job.

- There is still a lack of standards and regulations governing 3D printing. This makes it difficult for construction companies to know what is acceptable and what is not when using this technology.

- There is still a lack of trained personnel who can operate 3D printers. This means construction companies must train their own staff or outsource the work to third-party providers.

- Additive printing is not yet capable of producing structures of unlimited size. This means that construction projects that require very large structures (such as skyscrapers) cannot yet. Also, it’s limited by design for additive manufacturing rules.

Conclusion

3D printing is quickly becoming a staple in the construction industry. It offers many advantages over traditional methods, and its popularity is only going to continue to grow. As this technology continues to evolve, we expect to see even more impressive feats from the 3D printing construction community.