Project: Speehuis House

Architects: Spee Architecten

Lead Architect: Bart Spee

Structural Engineer: Raadschelders Bouwadvies

Location: Oisterwijk, The Netherlands

Area: 352 m²

Year: 2021

Photo credits: Ossip van Duivenbode

Speehuis House is not only unique in its appearance and location but above all, for its very sustainable and healthy design. The energy-neutral design consists virtually entirely of circular and bio-based materials.

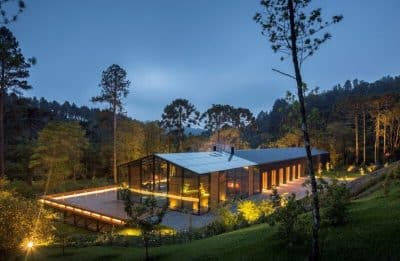

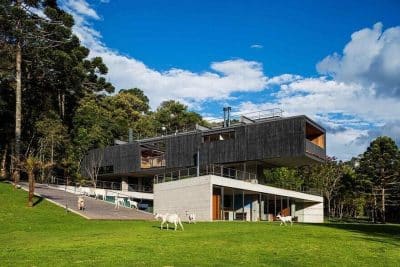

The Speehuis house is surrounded by a wooded area and built adjacent to a fen. By raising the house and providing verandas, which consist of bamboo slats and a recycled composite on all sides, there is a fine line between nature and the house which leaves the great outdoors to be easily accessible. As the garden is given back to nature and is devoid of the enclosure, the plot flows into the forest, offering beautiful views.

The facade and the sloping roof are finished with untreated ‘high density’ bamboo-composite slats which, due to their natural appearance, completely blend in with the verdant surroundings.

The house’s form, size, and layout are all tailored to the needs of a family with three children, while it also adjoins SPEE Architects’ office premises. The verandas and awnings are the connecting elements in the design of the building, which attach the office, home, and outdoor space to one another, thus unifying the former two. The dormers fitted in all bedrooms form an integral part of the sloping roof and exterior walls. The bedrooms are therefore highly spacious.

The staggered heights of the stories and expansive facades lend the rooms a sense of distinction, while invariably offering an all-around view of the greenery and mere. The detailing of the house was worked out meticulously, to ensure that the guttering and water bars are concealed, while the roof and wall cladding merge seamlessly with one another.

The spatial set-up, the composition of large facades, the verandas, the awnings, and the choice of sustainable materials jointly create a unique and contemporary living and working environment that becomes one with nature.

The Speehuis house is made of circular and biobased materials, which can be disassembled and adapted. For example, the facade and the sloping roof are made of untreated ‘high density’ (biobased) bamboo slats.

The exterior walls and sloping roof, for example, comprise untreated biobased ‘high density’ bamboo cladding with a concealed click-fixing system that can be conveniently dismantled. During the process applied to manufacture the ‘high-density bamboo – in which bamboo fibers and resin are compressed at high temperature – the natural sugar in the bamboo caramelizes, rendering it resistant to rot and therefore suitable for untreated application.

The entire shell, including the stairs, interior doors, desks, and cabinets, is made of sturdy cross-laminated timber (CLT), which lends the house a warm atmosphere. The prefabricated timber shell, including all the recesses to accommodate systems, was constructed within the space of a week. No discoloration occurs, thanks to the UV-resistant coating, and the timber, therefore, retains its aesthetically pleasing light color.

The sturdy timber structure is fully dismantlable, adaptable, recyclable, 30% lighter than concrete, and – similarly to the exterior cladding – manufactured using renewable raw materials. The decision to build using timber throughout also implies that a considerable amount of CO₂ is stored (rather than being emitted, as is the case with concrete) thus creating a healthy and more comfortable indoor climate.

150m3 of spruce wood has been used in the Speehuis, which means that 93,388 kg of CO2 is stored within the building. That is the equivalent of the annual electricity consumption of 103 households a year or the emissions of 784,773 kilometers of exhaust gases from a middle-class car. European forests store this amount of CO2 in 6 seconds. All the wood used in Speehuis comes from responsibly managed forests.

In comparison, the same building built in concrete would produce 46,694 kg of CO2. The total CO2 reduction by building in cross-laminated timber instead of concrete is therefore 93,388 kg + 46,694 kg = 140,082 kg CO2. By using a 9m3 bamboo composite as a facade material, an additional 15,736 kg of CO2 is stored. In addition to energy-efficient construction, storing CO2 in buildings is the solution to the climate problem.