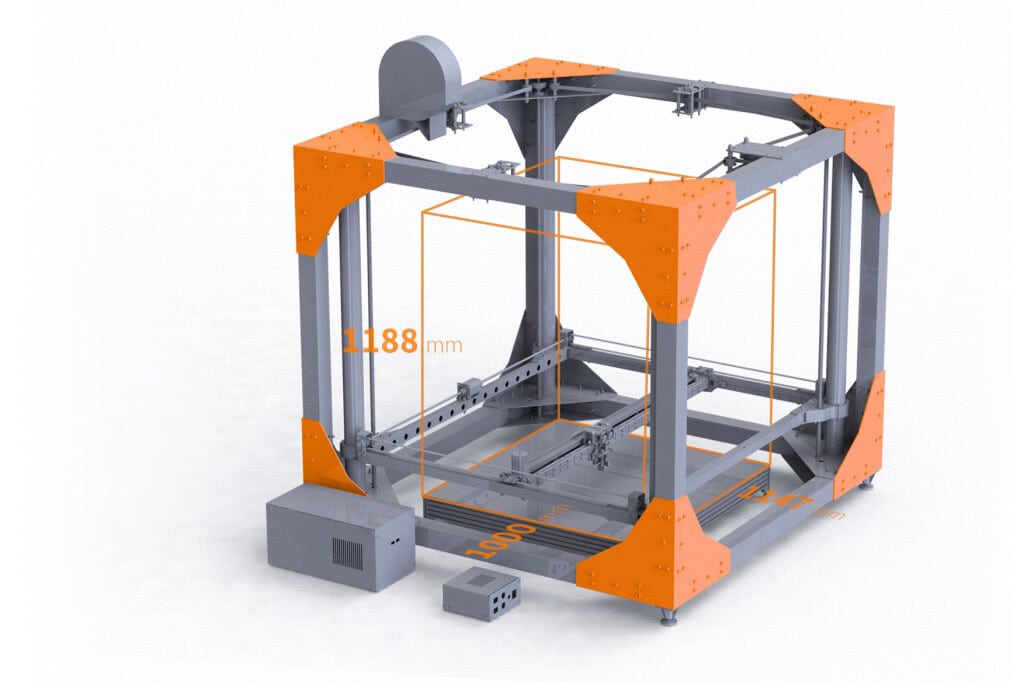

Do you think that pieces of furniture can be “drawn” at the printer? Let’s see what the German engineers think! The conventional 3D printers can usually produce only hand-sized objects. Established in 2014, BigRep company proposed itself to make a step forward in terms of 3D printing and open the way to a new dimension of 3D printing and production. With a printing volume bigger than one cubic meter, BigRep new 3D printer makes possible the production of prototypes and models at the scale of 1:1. Therefore, large-scale pieces of furniture can be created, including sophisticated furnishings, opening immeasurable opportunities to use.

The founders say: „The BigRep ONE can boast of being the biggest FDM 3D-Printer on the market, slashing the cost of a full-scale machine to 1/16 of its competitors’ market price. The Maker community now has access to large dimension 3D printing at a much lower price with the BigRep ONE. While having 27 times the volume of a large desktop 3D printer, it costs only about 5 times as much as the biggest makerbot machine.”

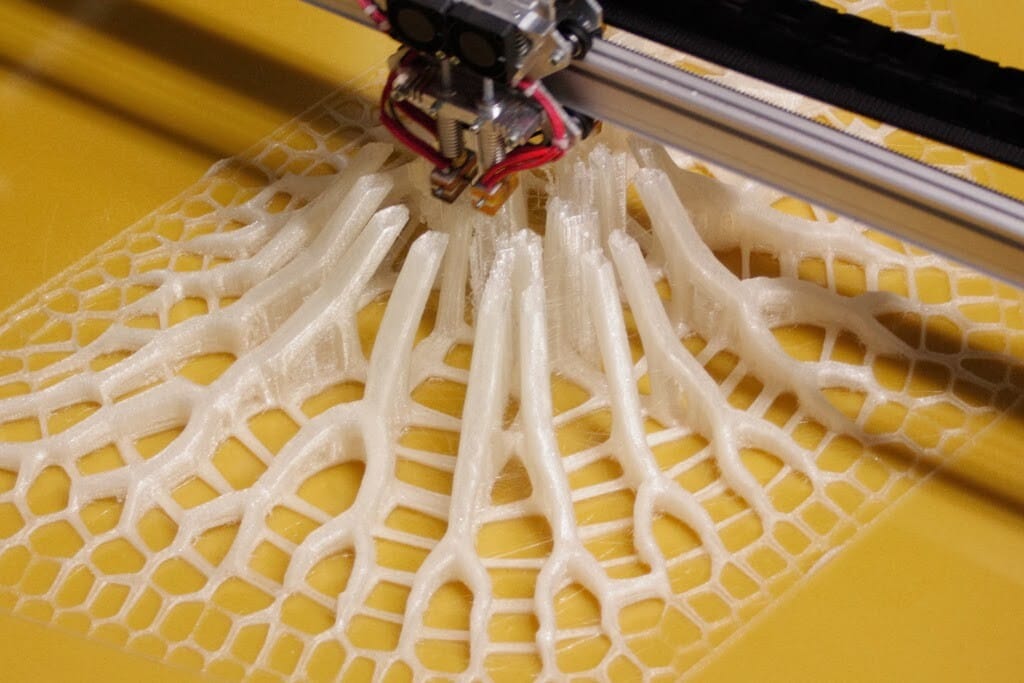

The printer is built so that it can be used in different environments, in industrial workshops or construction areas, in offices or studios. For the mass products, it greatly reduces the printing costs while it doesn’t make any compromises when it comes to accuracy. The printer is made in Berlin, Germany, being a real piece of “German engineering”. BigRep founders have roots in the field of arts, wherefore they say that they have created a machine that could produce works of art.